Service

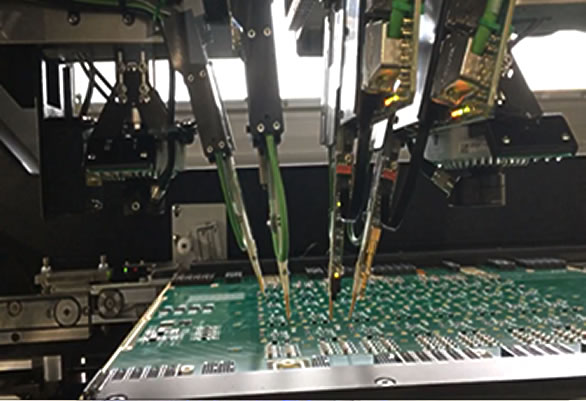

Features of Assembly

We can handle a wide range of needs, from short lead times for prototypes starting from a single sheet, to production of varying scales.

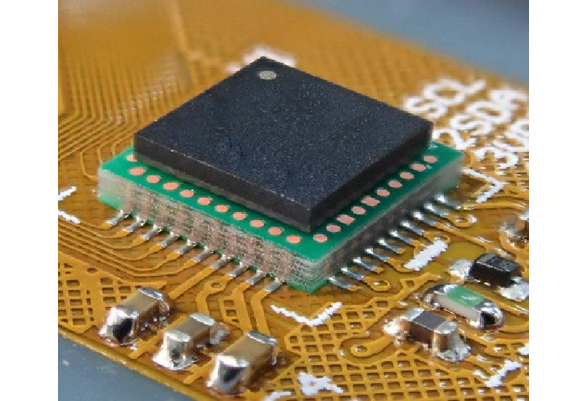

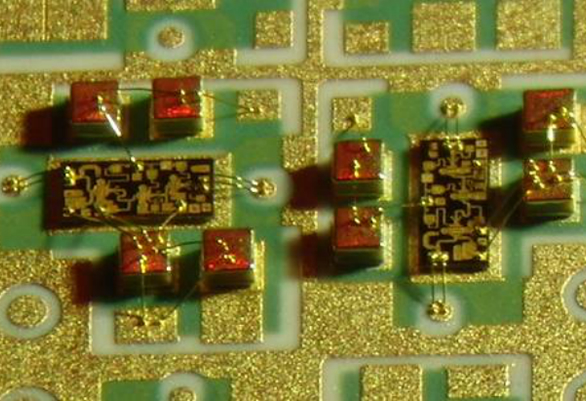

We also provide X-ray inspection equipment, 3D appearance image inspection equipment, and an inspection system using ICT, as well as special mounting such as BGA/CSP rework, flip chips, and wire bonding.

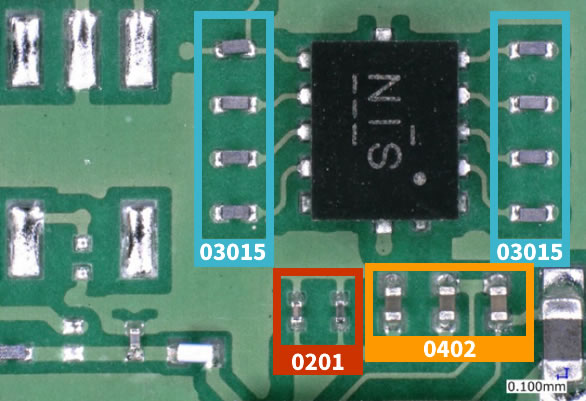

Implementation ability

| Size | 600×500mm |

| Plate thickness | 6.35t |

| Chip size | 0201 |

| Reflow | N2 compatible |

| Inspection equipment | X-ray, 3D image inspection, ICT |

Parts Procurement

With a diverse network of over 50 companies, both domestic and overseas, we can provide parts procurement with short lead times for small quantities of prototypes, low cost for mass production, and stable supply.

General-purpose resistors/capacitors (1005, 1608) are always in stock.

Various examples of support

| Ultra-small chip size mounting | 0201/03015 chip mounting |

| Rework | 0.35mm CSP rework, 0.4mm BGA reballing 0.5mm CSP ⇔ 0.5mm QFN conversion board 0.35mm CSP Jumper wire pull-out |

| Flip chip mounting | Minimum 250μm pitch Dicing compatible, NCP method compatible |

| ICT inspection equipment | Open/short check/LCR measurement |

| Wire bonding | Minimum 150μm pitch |